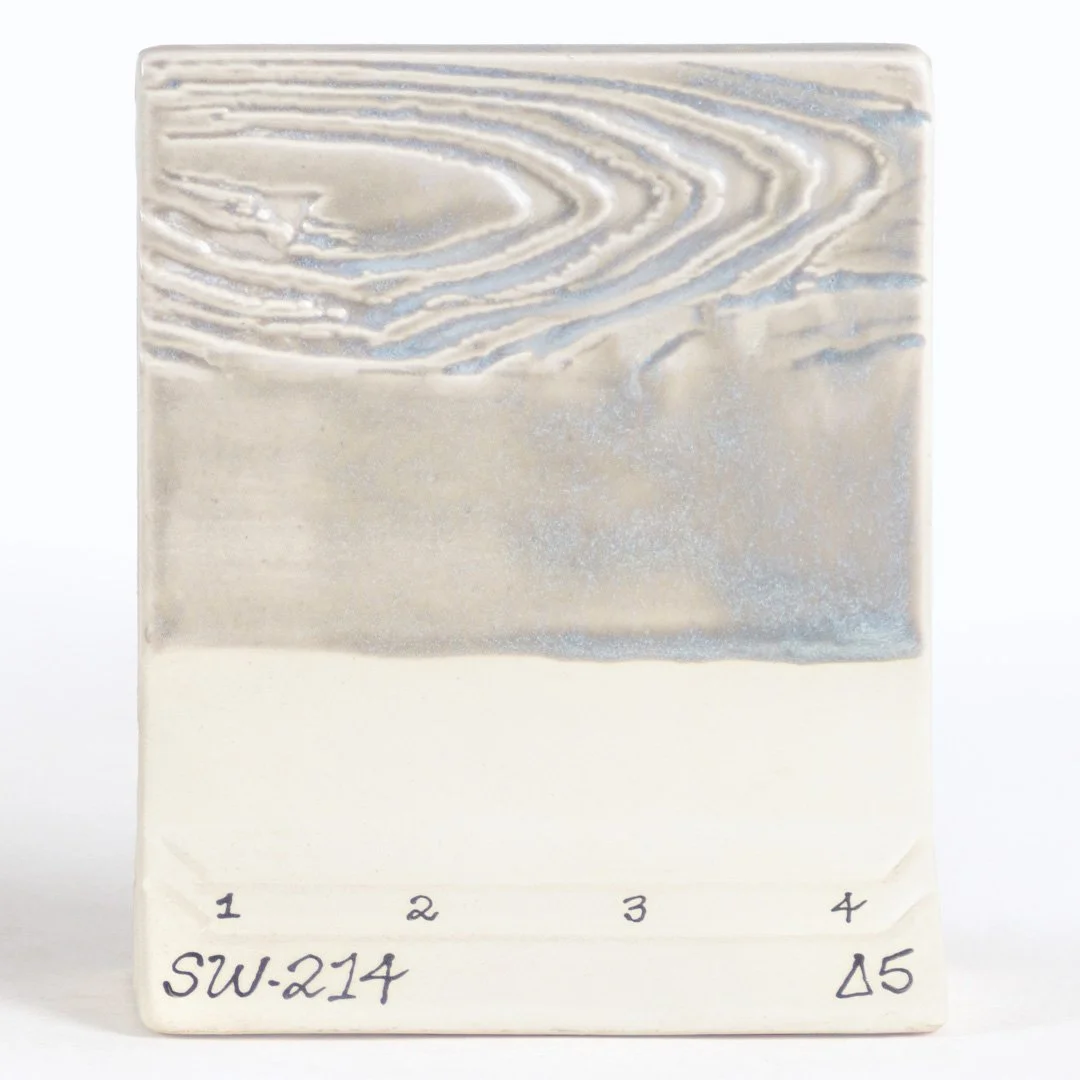

SW-214 Mirco Pearl

SW-214 Mirco Pearl

SW-214 - Pint (16oz)

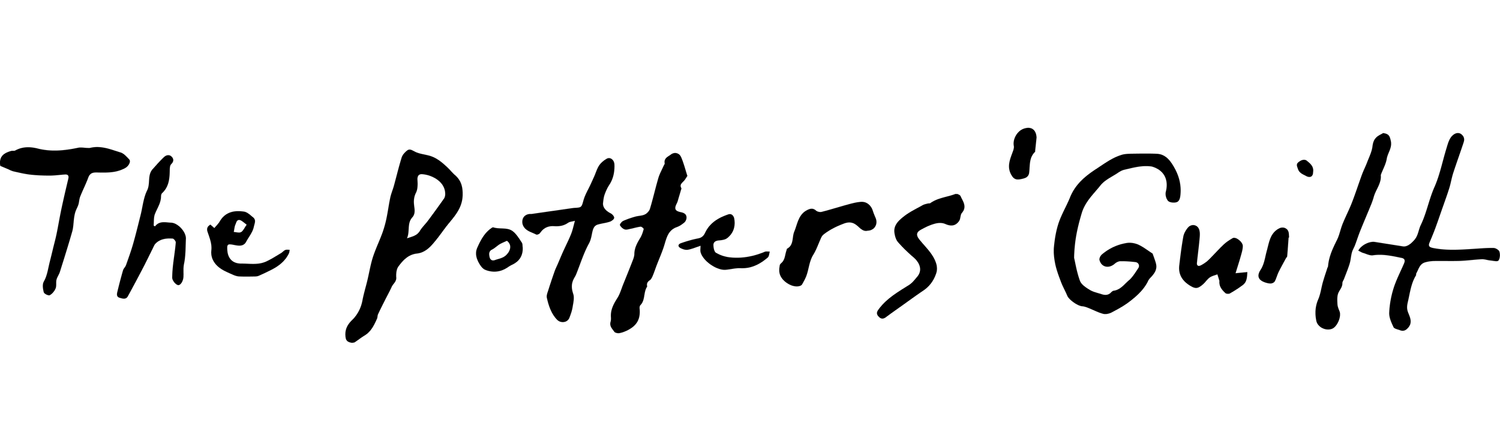

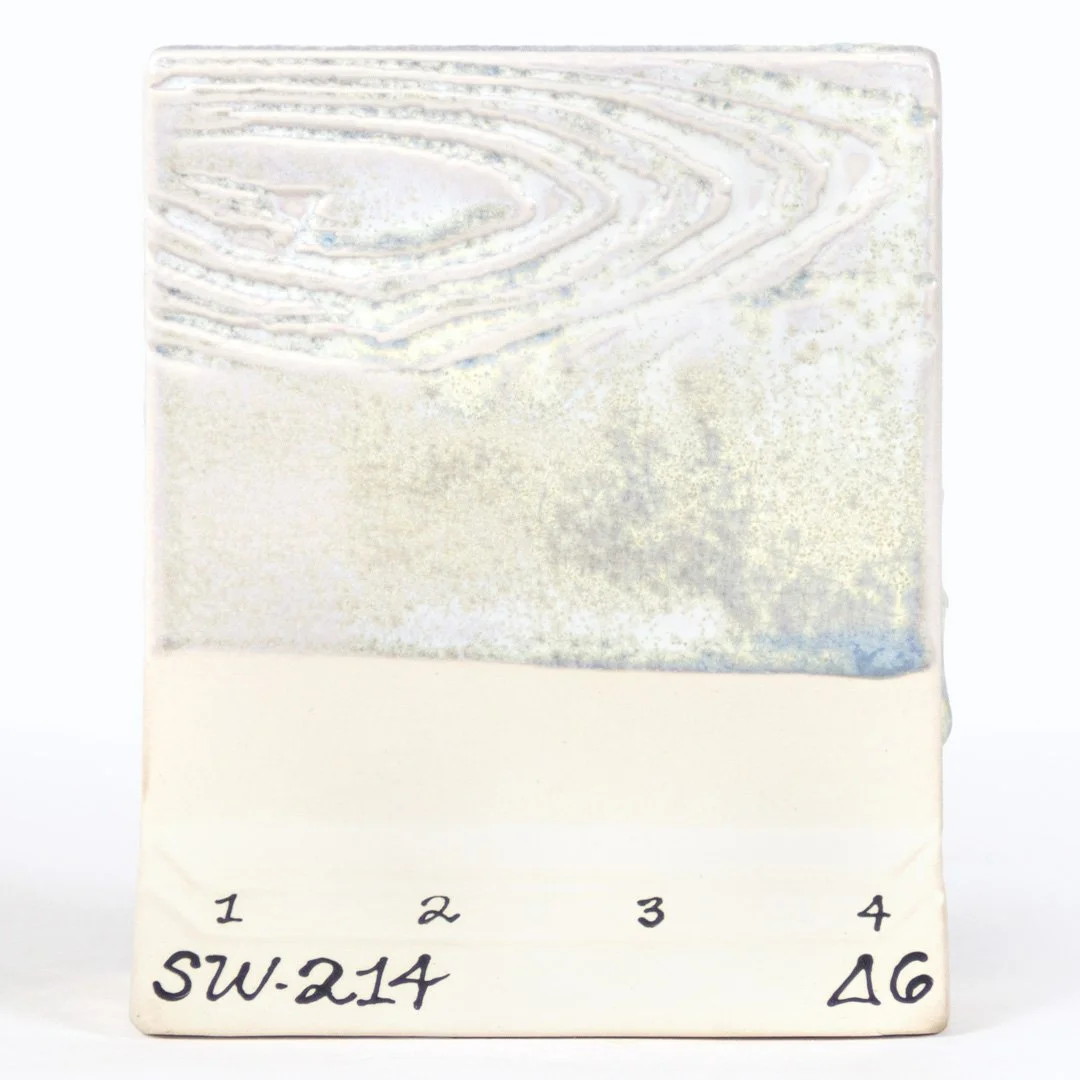

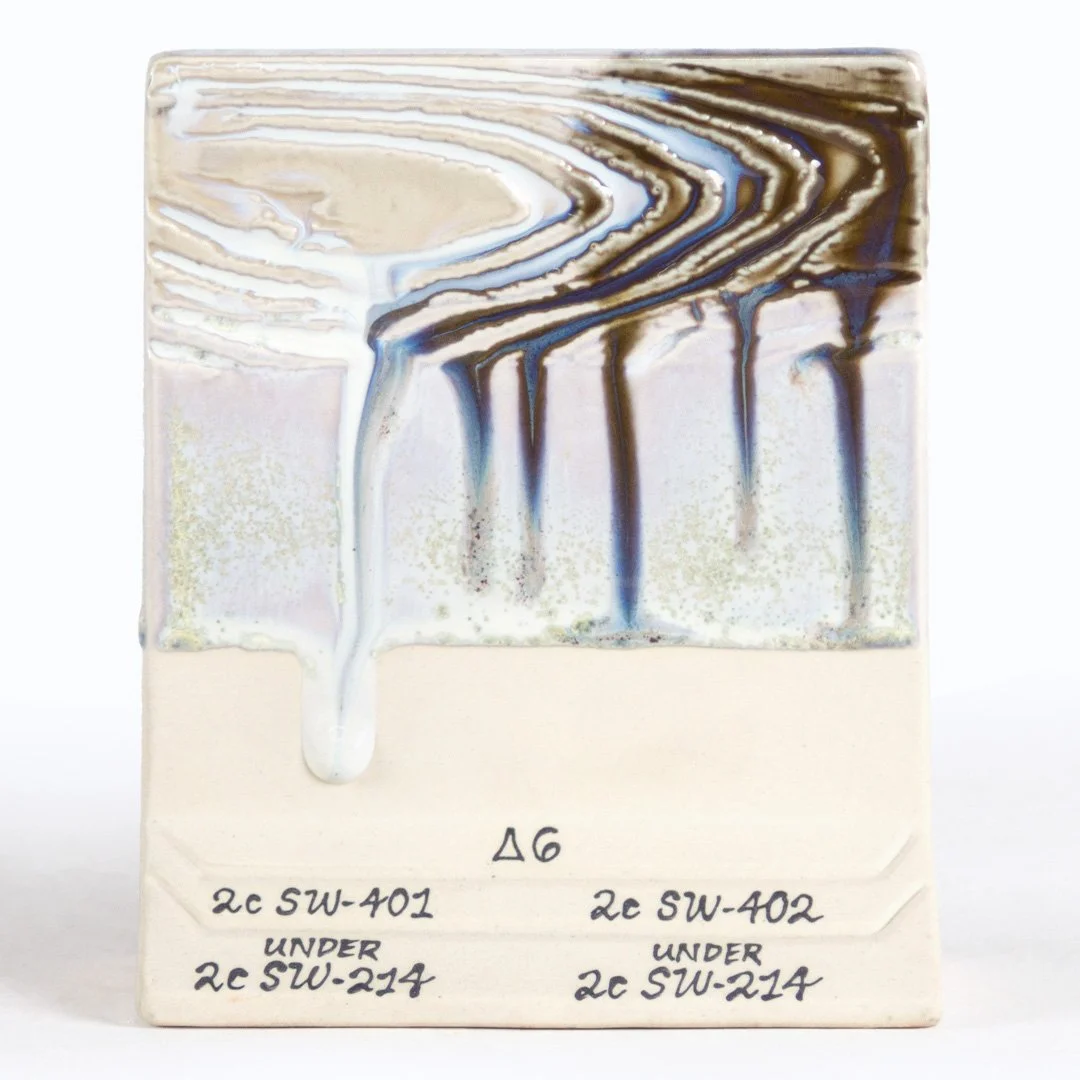

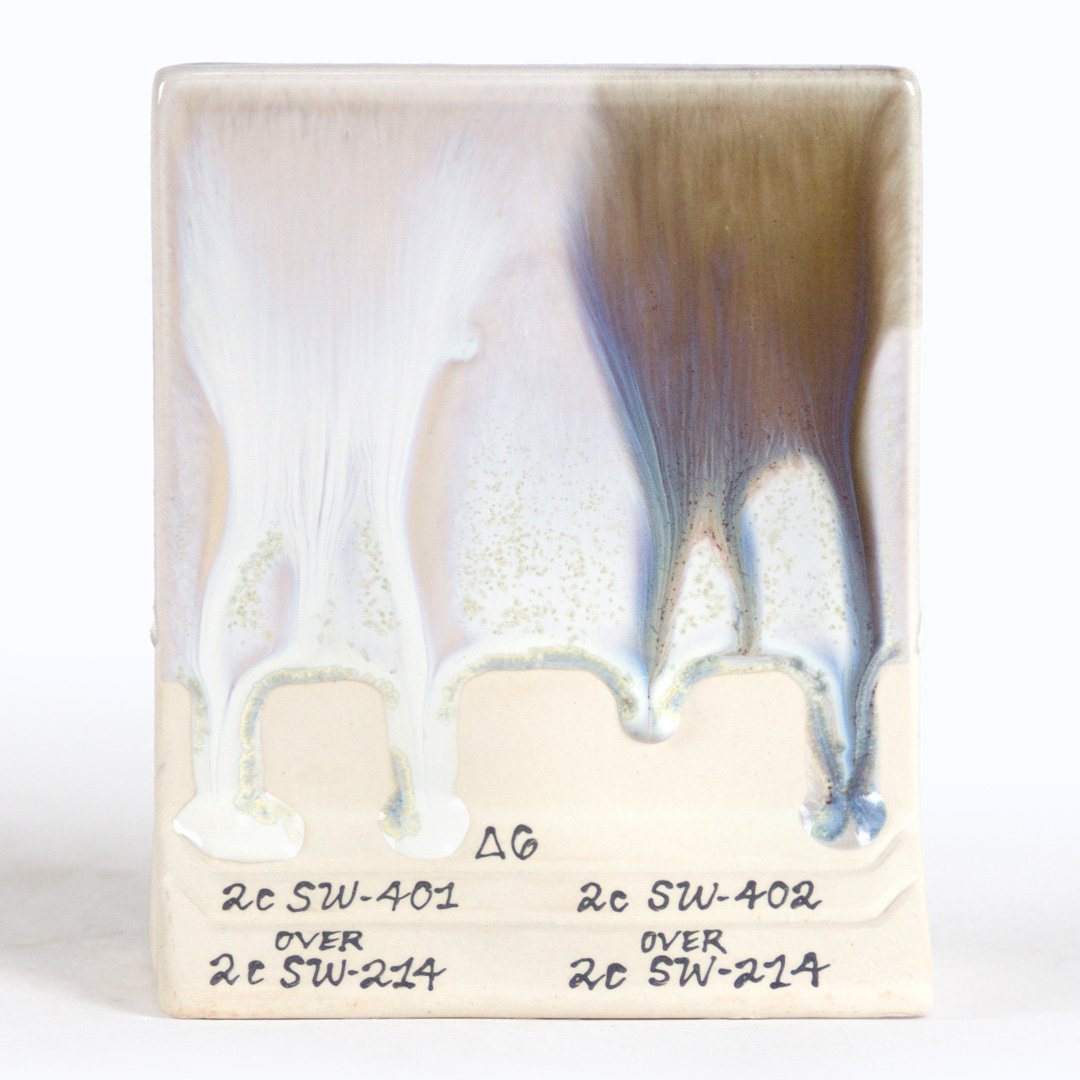

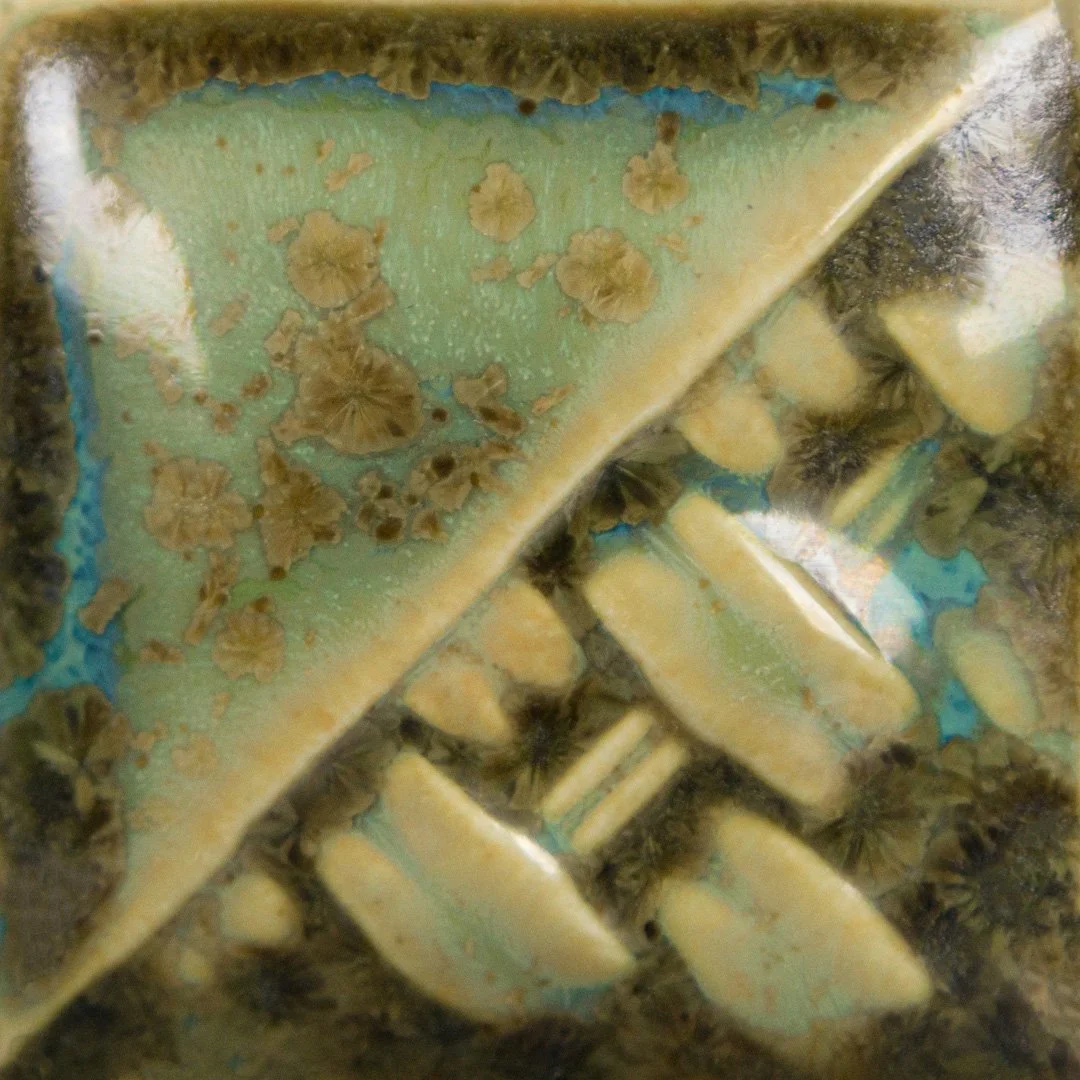

Cone 6 oxidation (larger image): Micro Pearl is a glossy, semi-opaque white glaze with lilac undertones that breaks over texture. Iridescent micro-crystallization in shades of lilac and pale yellow will develop during the firing process.

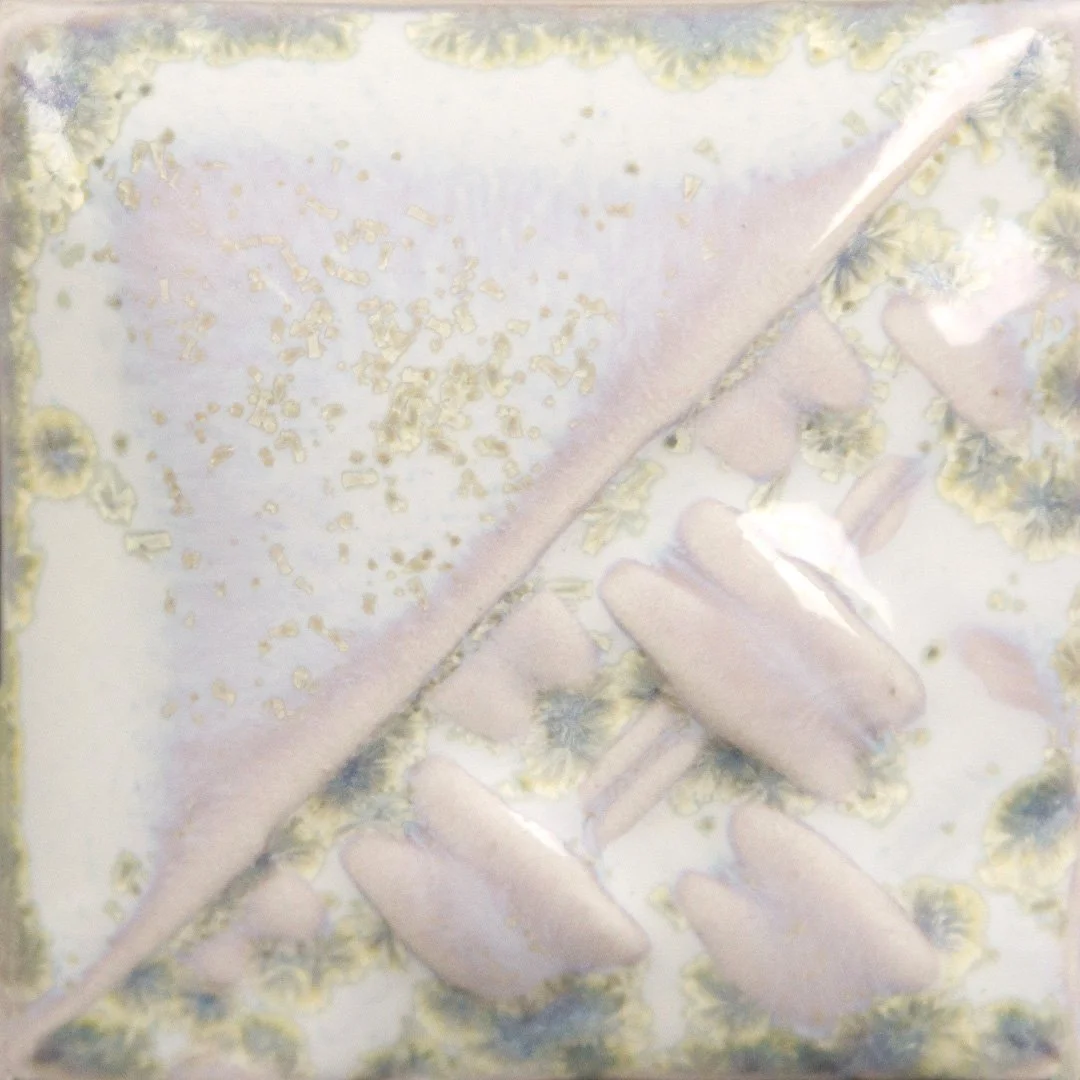

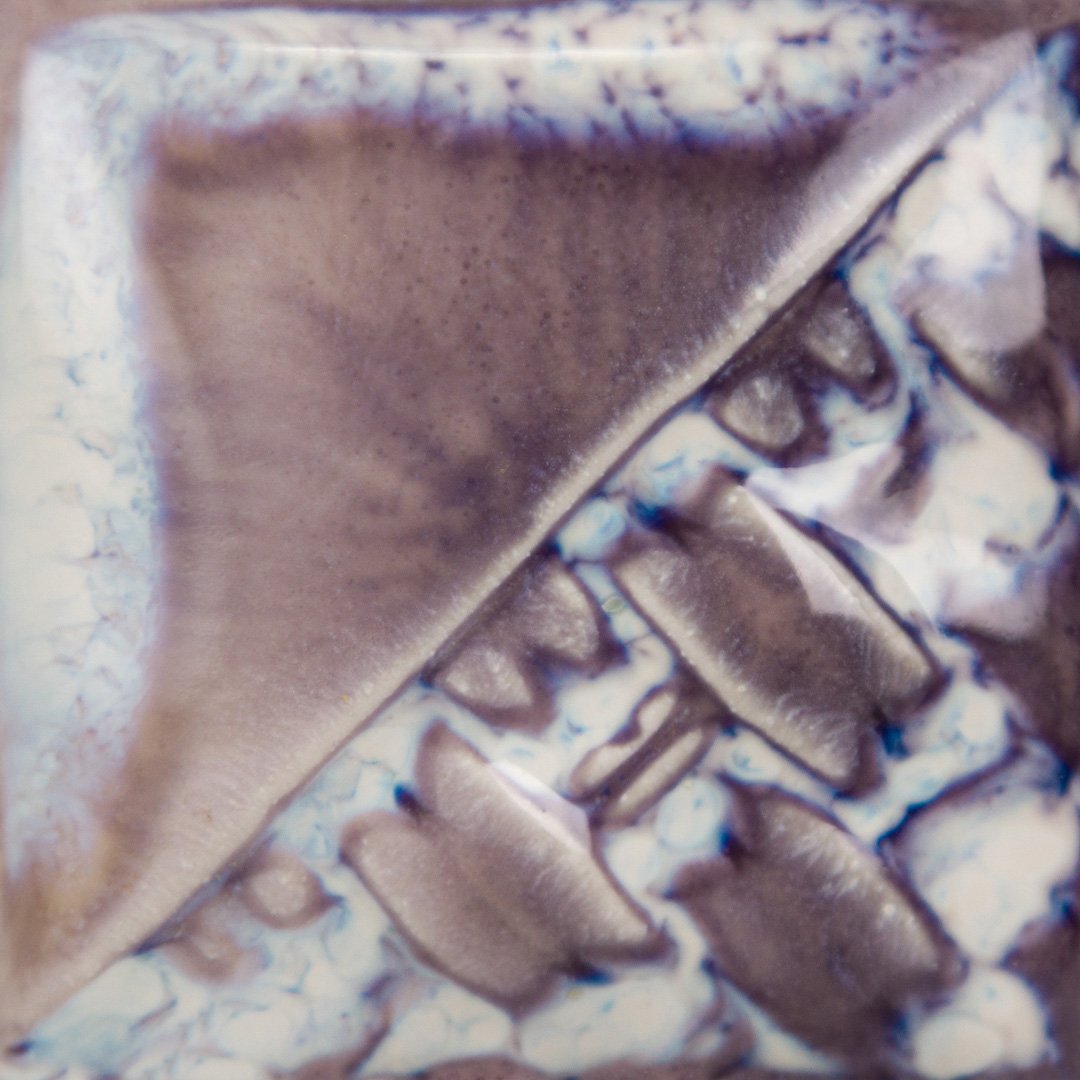

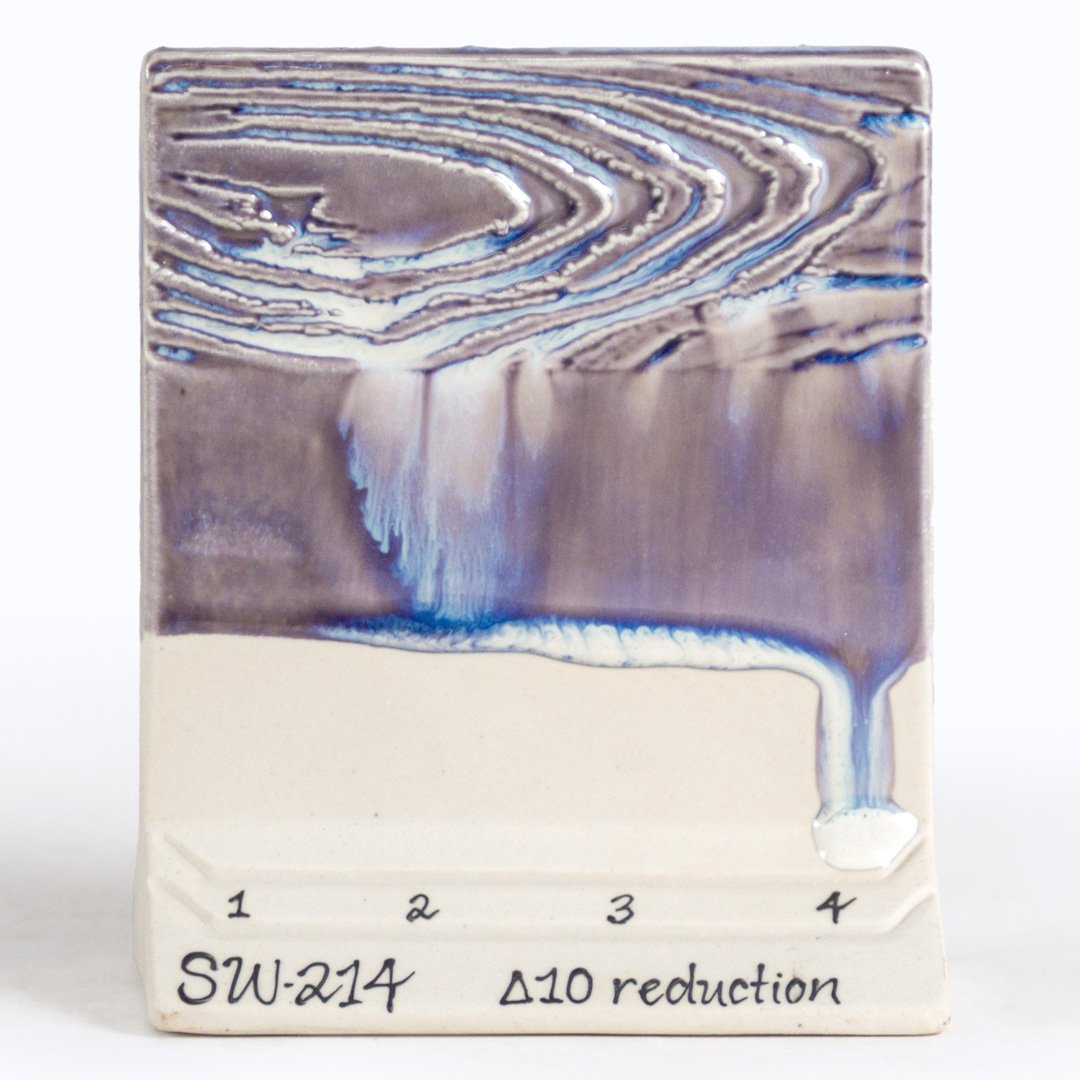

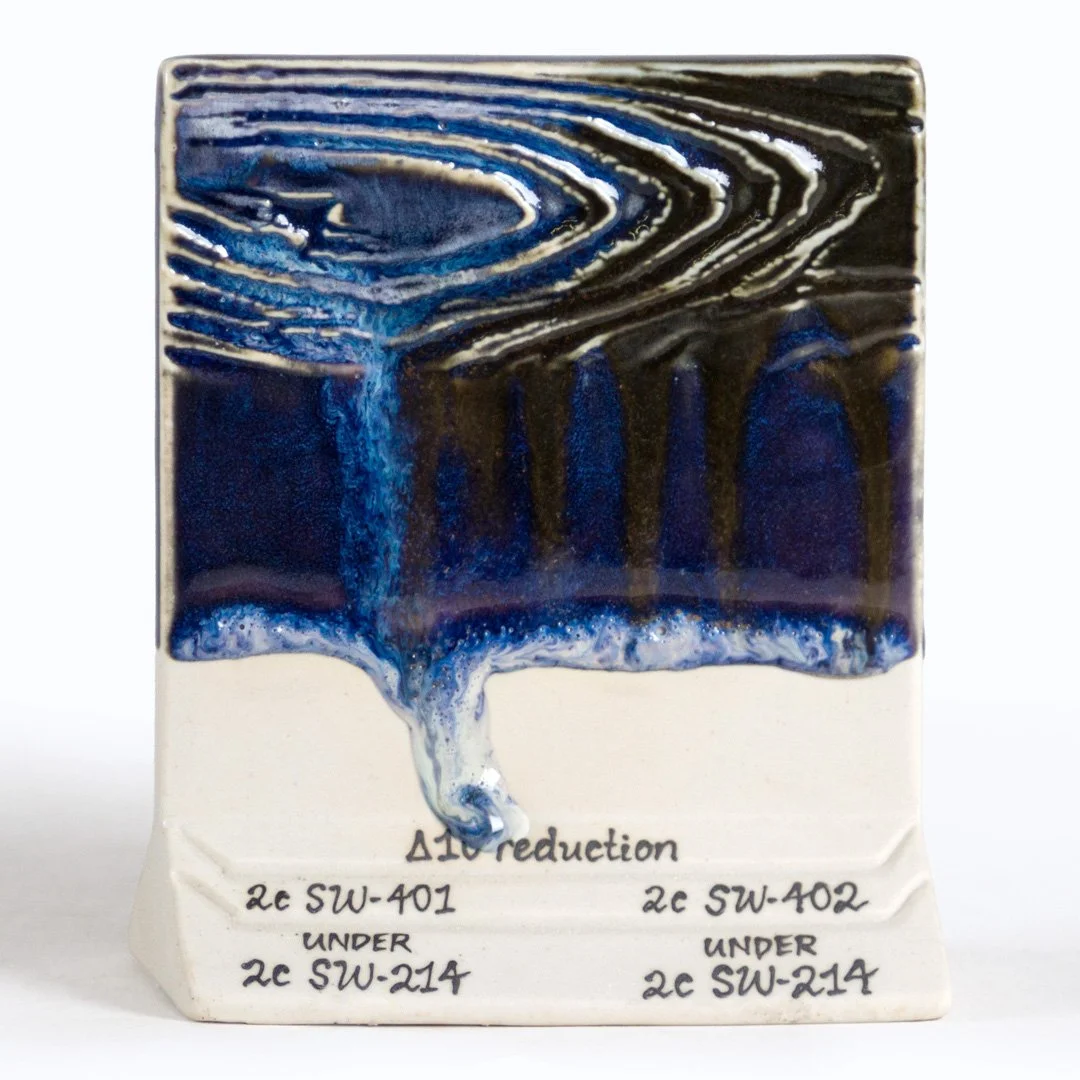

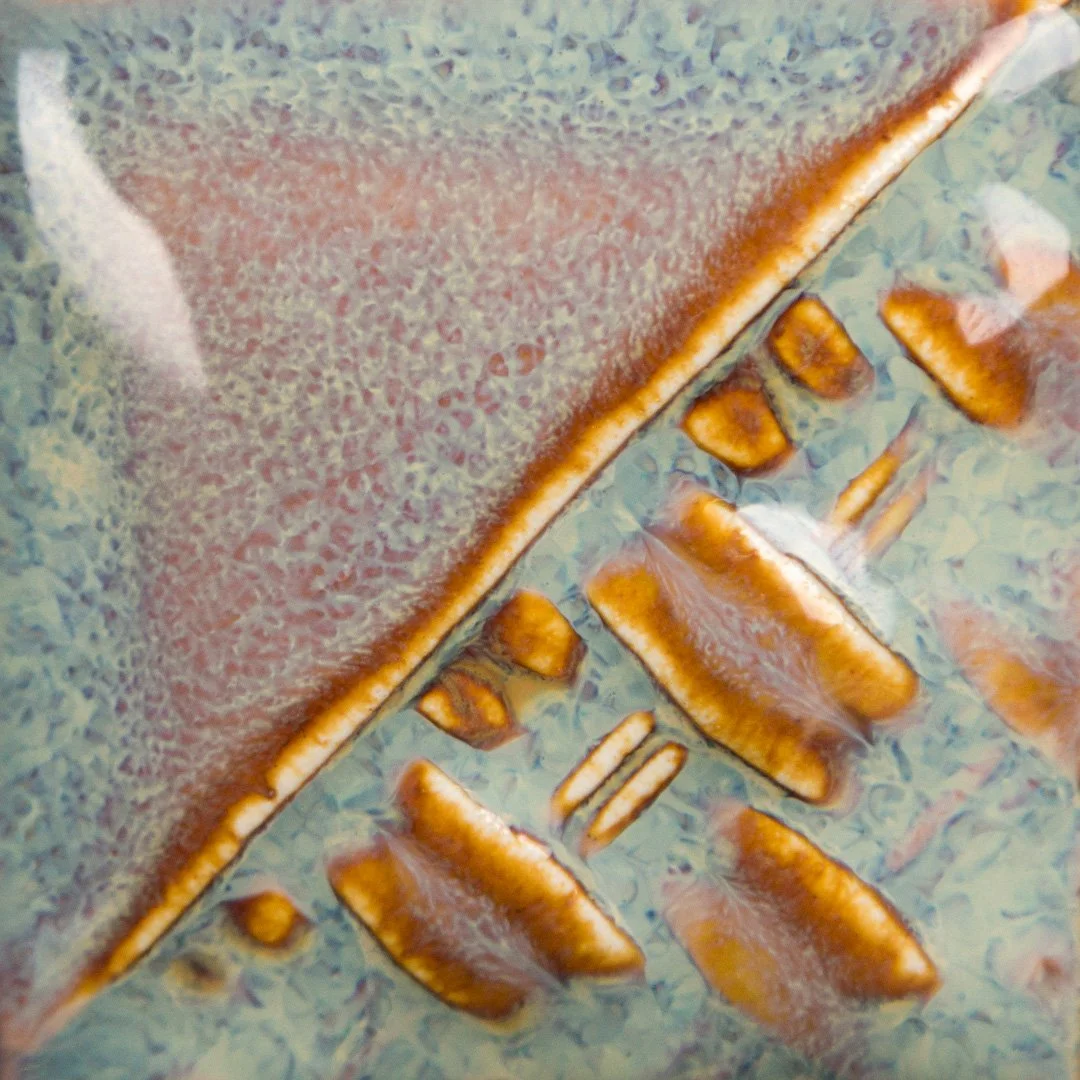

Cone 10 reduction (smaller image): Glaze darkens to blue, purple and white variegation.

TIP: This glaze is stable at 3 coats. Additional coats or increased application thickness may result in movement. We recommend firing our micro glazes to cone 6 oxidation to reach crystalline development. Micro-Pearl achieves a stable, semi-opaque, frosted white result with a pearlescent satin finish when fired to cone 5. Can be used in oxidation or reduction firings. Results may vary. The choice of clay body, thickness of application, firing process, and temperature will greatly affect the fired results. Always test your application on your clay body in your kiln environment.

Wood and soda firing results will vary.

Description

Stoneware classic glazes offer the depth, sophistication and reliability to artists working from mid-range to high-fire temperatures. Many glazes will break over textures, revealing secondary colors and shades. Used alone, stoneware glazes produce beautiful color variations. One coat will allow the clay body to show through the glaze and two to three coats deeper the color. The choice of clay body, thickness of glaze application, firing process and temperature will affect the fired finish.

Chips shown are fired flat on a white clay body fired to cone 6 oxidation and cone 10 reduction. The choice of clay body, the thickness of glaze application, the firing process, and temperature will affect the fired results.